- Condenser Design (CnD) CnD is a software that is made to demonstrate thermal analysis and design calculations required for designing shell and tube condensers. This software can design, horizontal shell side condensers, horizontal tube side condensers, vertical shell side condensers, vertical tube side condensers and reflux condensers.

- Tag: air cooled condenser design calculation excel. Air Cooled Condenser. June 30, 2018 September 6, 2019 hiadmin Heat Exchanger Leave a Comment on Air Cooled Condenser. Air Cooled Condenser: We are United Heat Exchanger providing solution for Air condensation system for all types of Thermal Power plants.In systems involving heat transfer, a.

- For detailed calculation than displays many selection and design of condensers 0 introduction purpose 1, isolated footing design example with step by step procedure and isolated footing design excel sheet.

Design of condenser 1. Introduction. A condenser is a type of heat exchanger in which vapors are transferred into liquid state by removing the latent heat with the help of a coolant such as water. Condensers may be classified into two main types: 1.

Condenser Calculation, Using Thermo Utilities, MS Excel Add-ins

A surface condenser is required to deal with 15 000 kg/h wet steam. Wet steamtemperature is 37 C and enters the condenser with 0.95 quality (dryness fractionis 0.95). The water used for cooling has the following data:

- Inlet pressure 1.20 bar, inlet temperature 7 C

- Outlet pressure 1.013 bar, outlet temperature 22 C

Calculate the flow rate of cooling water and tube surface of the condenser.Assume that the cooling water velocity through tubes is 1.5 m/s

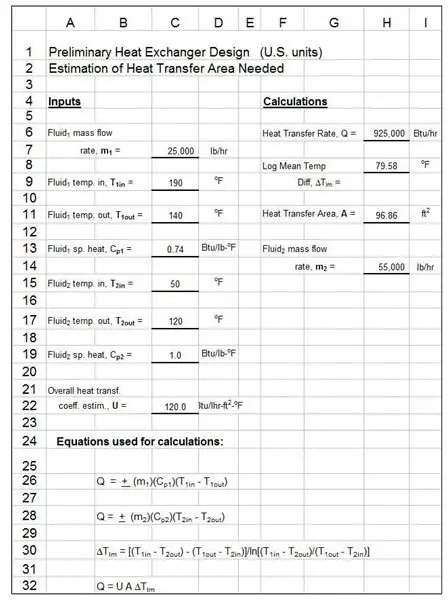

| Inputs | Units | |

Wet steam inlet temperature | 37 | C |

Steam quality | 0,95 | . |

Cooling water inlet temperature | 7 | C |

Cooling water inlet pressure | 1,2 | bar |

Cooling water outlet temperature | 22 | C |

Cooling water outlet pressure | 1,013 | bar |

Steam mass flow | 15000 | kg/h |

Cooling water speed | 1,5 | m/s |

Outputs | . | . |

Wet steam pressure | 0,06274 | bar |

Enthalpy of steam at inlet | 2448,28 | kJ/kg |

Entropy of condense | 154,92 | kJ/kg |

Rejected heat/hour | 34400441,72 | kJ/h |

Rejected heat/second | 9555,68 | kJ/s = kW |

Enthalpy of water at inlet | 29,53 | kJ/kg |

Enthalpy of water at outlet | 92,31 | kJ/kg |

Water mass flow | 547885,14 | kg/h |

The overall heat transfer coefficient can be calculated according to BEAMAor HEI standards.

BEAMA: British Electrical and Allied Manufacturers Association

BEAMA publication on the recommended practice for design of surface typesteam condenser

HEI: Heat Exchanger Institute

HEI standards for steam surface condensers

| Outputs | Unit | |

Heat transfer coeff.(BEAMA) | 2,95235 | KW/m2,K |

Logarithmic mean temp. diff. | 49,83 | degree K |

Required area | 64,96 | m2 |

| Outputs | Unit | |

Heat transfer coeff.(HEI) | 3,60991 | kW/m2,K |

Required area | 53,12 | m2 |

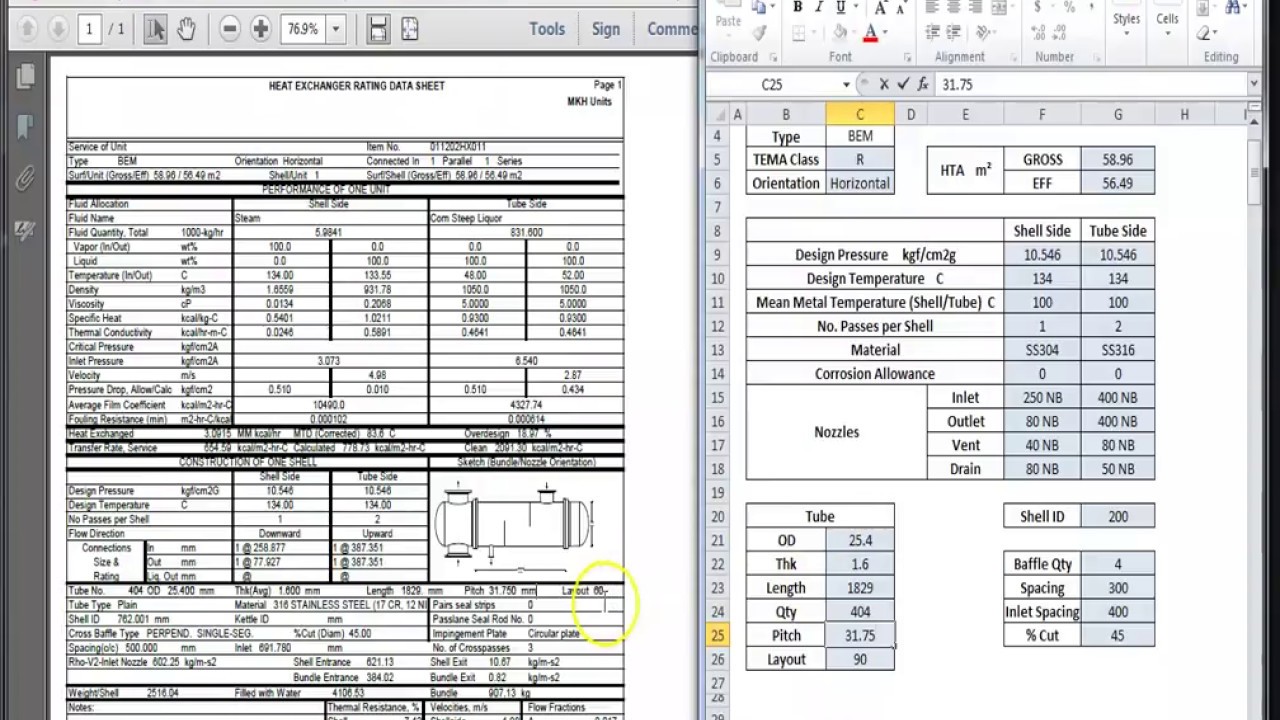

Shell And Tube Condenser Design Calculation Excel

Surface condenser design calculation

Surface condenser design calculation

Condenser Design Calculation Excel Example

I want to learn to design surface condenser base on HEI standard, I would be very grateful if someone can tell me how I should start learning it?

Is there any software for designing surface condenser based on HEI standard (Like HTRI or Aspen EDR that are based on TEMA Standard)? ( I googled it but I could not find anything)

Does the HEI standard is enough for design calculation or I need another reference (book or handbook) ?( if another reference is necessary please let me know)

It would be very helpful if you could send me an example of designing surface condenser because I really don't know what I should do or what book or Handbook I should read.

Best regard,

Morteza